Introduction

How much time does your team waste hunting down missing laptops and servers? IT asset tagging transforms chaotic equipment tracking into streamlined systems that save time and prevent losses. By attaching device asset tags to every piece of hardware, organizations gain instant visibility into their equipment’s location, status, and lifecycle. This guide builds on the fundamentals of asset tagging and reveals how to implement effective IT asset tagging strategies that can reduce audit time by up to 70%.

In this guide, you’ll learn:

- What IT asset tagging is and how it supports effective IT asset management (ITAM).

- Why tagging IT hardware improves inventory accuracy, audits, compliance, and security.

- How to choose between RFID and barcode tagging for different IT environments.

- How to tag and track IT assets step by step, with a real-world AssetCues case study.

What is IT Asset Tagging?

IT asset tagging involves assigning unique identifiers to physical IT equipment and affixing trackable labels for monitoring purposes. Each device asset tag contains a barcode, QR code, or RFID chip that connects hardware to its digital record. Scanning these tags instantly reveals crucial information like ownership details, location history, and maintenance schedules.

For instance, scanning a barcode on a company laptop immediately displays the device’s serial number, assigned user, purchase date, and warranty status. Therefore, asset tags create a reliable connection between physical equipment and digital records, making updates effortless and audits straightforward.

Why is IT Asset Tagging Important?

Effective asset tagging addresses critical business challenges while delivering measurable benefits. Many organizations struggle with incomplete asset records, and a portion of listed assets cannot be physically verified. However, implementing proper IT asset tagging resolves these gaps through key advantages:

1. Improved Inventory Accuracy:

Each asset receives a unique tag for precise tracking, eliminating manual counting errors. This dramatically increases inventory accuracy and ensures your asset list reflects reality. Furthermore, it prevents “ghost assets” from appearing on financial records. This is critical for IT departments tracking endpoints, servers, and network assets across offices, data centers, and remote locations.

2. Cost Savings & Efficiency:

Scanning asset tags proves faster and more reliable than manual methods. As per industry insights, businesses adopting automated tagging see a 30–50% drop in audit-related labor costs. Additionally, it prevents over-purchasing by revealing underutilized equipment already in stock.

3. Compliance and Audit Readiness:

Up-to-date tagged records make regulatory audits smoother and faster. A clearly defined IT asset tagging policy ensures accurate records for financial reporting and compliance requirements. Consequently, auditors can verify assets quickly by scanning tags, helping organizations meet ITIL, IFRS, or SOX standards with minimal hassle.

4. Lifecycle Management:

Tags connect each device to its comprehensive digital profile, including warranty information and maintenance logs. This supports proactive lifecycle management from procurement through disposal. Therefore, teams can schedule maintenance, track depreciation, and determine optimal replacement timing.

5. Accountability & Security:

When every device is tagged and logged, clear ownership accountability emerges naturally. Meanwhile, employees become less likely to misplace or steal tagged items since missing assets are quickly noticed.

RFID vs. Barcode Tracking for IT Assets

Organizations often wonder whether to implement RFID IT asset tracking or traditional barcode systems. Both technologies offer unique advantages depending on your specific requirements. RFID tags contain small radio transmitters enabling wireless reading, while barcodes require direct line-of-sight scanning.

|

Factor |

RFID IT Asset Tracking |

Barcode Asset Tracking |

|

Scanning Method |

Wireless reading without direct line-of-sight; can scan multiple tags at once. | Optical scanning requires line-of-sight and scans one item at a time. |

|

Read Range |

Long range (RFID readers can detect tags from several feet away, even up to 30 feet with UHF). | Short range (scanner must be within inches to a few feet of the barcode). |

|

Tag & Equipment Cost |

Higher cost per tag and infrastructure. RFID tags often cost $0.10 to $5+ each, and readers are expensive. | Very low cost. Barcode labels cost only a few cents each, and most offices already have inexpensive scanners (or even smartphone apps). |

|

Inventory Accuracy |

Extremely high – RFID systems can achieve ~99% inventory accuracy by quickly scanning all assets, reducing human error. | High but lower – manual barcode scans yield around 85% accuracy on average, as items might be missed or data entry errors occur. |

|

Durability |

Tags can be very durable (e.g. rugged RFID tags survive harsh environments). Also, RFID tags can be embedded inside equipment. | Labels are prone to wear (can fade, scratch or fall off over time). Durable polyester or metal barcode tags can mitigate this but still may need replacement if damaged. |

In summary, RFID tracking works best for large volumes or fast, automated scans like data centers. Additionally, RFID doesn’t require line-of-sight and speeds up inventory counts. However, it is more costly to implement.

On the other hand, barcodes suit smaller scale or budget-conscious tagging. They are cheap, simple, and ideal for one-by-one scanning. In fact, many organizations use both: barcodes for general IT and RFID for high-volume or critical assets.

Ultimately, choose the method that matches your needs and budget. Either way, asset tagging will enhance your ITAM process.

How to Tag and Track IT Assets (Step-by-Step)

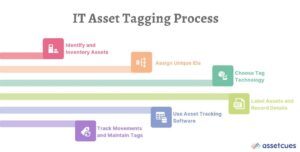

Setting up an effective IT asset tagging system requires following a systematic implementation process. Here’s a comprehensive step-by-step guide:

IT asset tagging involves identifying hardware, assigning unique tags, and recording asset details in an IT asset management system. By tracking movements and updates through regular scans, organizations maintain accurate inventories and prevent asset loss.

-

Identify and Inventory Your Assets:

Begin with a complete hardware inventory of all trackable IT equipment. Conduct a thorough physical count of computers, laptops, servers, networking gear, and peripherals. This ensures you understand exactly what items require tagging.

-

Assign Unique IDs to Each Asset:

Next, establish a consistent identification scheme for every item. Often this involves asset ID numbers or codes for each piece of equipment. The key requirement is that every asset gets its own unique ID that corresponds to its physical tag.

-

Choose the Right Tag Technology:

Decide on appropriate asset tag types for your operational needs. For most IT hardware, you’ll choose between barcode labels or RFID tags based on the comparison above. Also consider tag materials – durable labels for laptops experiencing heavy use, or tamper-evident labels for sensitive devices.

-

Label the Assets and Record Details:

Once you have the tags, affix them to each asset in consistent, visible locations. As you tag each device, scan the tag and enter it into your ITAM system along with complete asset details. This step links the physical tag to the digital asset record.

-

Use Asset Tracking Software:

Leverage comprehensive IT asset management software to monitor your tagged assets effectively. The software should allow you to scan tags via barcode scanners or RFID readers to quickly access or update asset information. This makes audits and updates straightforward.

-

Track Movements and Maintain Tags:

With everything tagged and systematized, establish procedures for ongoing tracking activities. Train staff to scan asset tags when moving or servicing equipment so location and custody updates are recorded accurately. Schedule periodic audits where you scan assets to verify presence and data currency.

Case Study: AssetCues in Action

AssetCues helped a large chemicals and fertilizers company overhaul its asset tracking process completely. The company struggled with slow manual audits and frequent equipment losses. AssetCues implemented a comprehensive barcode and RFID tagging solution for all hardware and integrated it with their existing ITAM system.

The results were remarkable – the company saved over 70% in time and cost for physical asset verification. What previously required weeks of auditing across multiple sites was reduced to efficient scanning routines. AssetCues’ platform also enabled managers to view real-time asset locations and maintenance statuses, leading to better asset utilization and compliance during audits.

Key Takeaways

- Overall, IT asset tagging enables accurate tracking of hardware assets, reducing time spent searching for devices while improving inventory accuracy and audit readiness.

- By choosing the right tagging method—barcodes for cost efficiency or RFID for scale and speed—and integrating it with ITAM software, organizations streamline audits, prevent asset loss, and control IT costs.

- Finally, consistent scanning, lifecycle updates, and user accountability turn IT asset tagging into an ongoing control mechanism, supporting compliance, security, and long-term IT operations.

Conclusion

IT asset tagging represents a simple yet powerful practice to track all hardware assets within your ITAM framework. Through IT asset inventory tagging, each device is labeled and monitored using software, enabling accurate inventories, streamlined audits, cost savings, and improved accountability. Whether you choose barcodes or RFID, the key is starting your tagging initiative and integrating it into a reliable asset tagging system that supports long-term asset control and compliance.

The benefits are clear: fewer lost devices, eliminated spreadsheet guesswork, and complete visibility of your IT assets. If you’re ready to elevate your IT asset tracking capabilities, now is the time to take action. Consider exploring comprehensive solutions that can guide you through implementation and provide ongoing support for your asset management needs.

FAQ

Q1: What is a device asset tag?

Ans: A device asset tag is a physical label attached to equipment containing a unique identifier (barcode, QR code, or RFID chip). Scanning the tag instantly pulls up that device’s details in an asset management system.

Q2: How does RFID IT asset tracking work?

Ans: RFID IT asset tracking uses radio-frequency identification tags on assets. Each RFID tag contains a tiny antenna and chip storing an ID. When you bring an RFID reader near tagged equipment, the tags transmit their IDs wirelessly.

Q3: Should we use RFID or barcodes for IT asset tagging?

Ans: It depends on your needs. Barcodes are inexpensive and simple – perfect for small inventories or tight budgets. RFID works better for large or frequently changing inventories because it can scan multiple tags simultaneously without line-of-sight requirements.

Q4: How does asset tagging save money?

Ans: Asset tagging saves money by improving efficiency and preventing losses. First, it cuts audit and inventory labor costs since scanning tags is quick and accurate. Second, it prevents buying duplicate equipment by maintaining accurate inventory records. Finally, it reduces losses from theft or misplacement.

Q5: How can we get started with IT asset tagging?

Ans: Start with a pilot project: identify a specific set of IT assets and implement tagging for them. Choose a tagging method, label each device, and record details in an ITAM tool. Train your team to use the system, evaluate results, then expand across all hardware.