Introduction

Misplaced tools and missing equipment can grind operations to a halt. Every lost wrench or unaccounted machine not only delays projects but also hits the bottom line. Across job sites, workers lose significant time searching for tools instead of doing productive work, while equipment losses quietly drive up replacement and downtime costs. These compounding losses highlight why physical asset tagging has become essential for modern operations In industries such as construction, manufacturing, utilities, and infrastructure projects, a reliable tool tracking system is critical to prevent losses, control costs, and keep operations running smoothly.

Equipment tagging means attaching a durable identifier like a barcode, QR, or RFID. Each tag carries a unique ID that enables accurate tracking and identification. When integrated with asset management software, tags provide real-time visibility and accountability. This process transforms tools into traceable assets, preventing losses and ensuring reliable oversight.

(Tip: Consider integrating tags with an asset tracking software platform like AssetCues, which serves as a central database for all tagged assets.)

In this guide, you’ll learn:

- What tool and equipment tagging is and why it matters for loss prevention, productivity, and accountability.

- How barcode, RFID, and GPS-based tagging systems work, and when to use each.

- How to implement an effective equipment tagging system step by step to reduce theft and downtime.

Why Tagging Tools and Equipment Matters

Lost equipment isn’t just an annoyance – it’s a preventable expense. Tagging assets creates a digital inventory that dramatically improves accountability and reduces loss. Here are key reasons an equipment tagging system is a smart investment:

-

Prevent Theft & Loss:

When every tool is tagged and tracked, losses from theft or misplacement decrease. Without tracking, companies risk losing millions annually to missing equipment and theft. Tagging deters misuse since monitored assets resemble security cameras discouraging shoplifters. Moreover, tagged assets provide alerts and traceable data, reducing losses and enabling quick recovery. This is especially important for asset tagging in construction, where tools frequently move between job sites, crews, and subcontractors.

-

Improve Efficiency & Productivity:

Tagged tools are easy to locate, eliminating wasted time on job-site searches. Workers often lose hours daily searching for untracked tools, hurting productivity. With tags, managers instantly access last known locations or scan to identify items. Consequently, less searching directly translates into more productive and efficient work hours.

-

Inventory Accuracy & Audit Readiness:

Tagging builds a reliable asset inventory while eliminating uncertainty about equipment ownership. Moreover, tagging ensures accurate records for audits, insurance, and depreciation. Consequently, Audit and Finance Managers gain clarity on ownership, location, and condition, ensuring compliance and avoiding surprises.

-

Maintenance & Lifecycle Management:

Tags connect directly to asset histories like maintenance schedules and usage logs. Technicians can instantly scan a tag to access records and ensure timely service. Collected data on breakdowns and performance supports smarter repair-or-replace decisions. Ultimately, tagging extends equipment life and reduces downtime by preventing missed maintenance.

-

Cost Savings & ROI:

All these benefits deliver measurable financial savings and stronger operational efficiency. Fewer lost tools lower replacement costs, while better utilization prevents unnecessary duplicate purchases. Companies using RFID tagging report fast ROI through reduced losses and labor savings. With the market projected at $3.4 billion by 2035, organizations increasingly adopt tagging to achieve near-zero missing tools and higher revenue.

Holt-Cat’s quick ROI demonstrates that an investment in tagging technology can pay back in months, not years. This kind of success story shows how effective tool tagging can drastically cut losses and boost productivity.

Equipment Tagging Systems and Technologies (RFID, Barcodes & More)

There’s no universal tag; however, modern equipment tagging systems provide multiple technologies. You can mix and match methods depending on operational needs and budgets. Moreover, these systems offer flexibility, ensuring the right fit for different environments. Here are the most common tagging methods used for tools and equipment.

Barcode & QR Code Tags – Affordable and Effective

Barcodes remain a classic, cost-effective, and widely trusted solution for asset tagging. Simple barcode or QR code stickers allow scanning via handheld readers or smartphones. They work best in controlled environments like warehouses, though requiring line-of-sight. With durable materials available, barcodes remain a reliable workhorse for inventory tracking.

RFID Tool Tracking – High-Tech Tags for Real-Time Visibility

RFID revolutionizes tool tracking by enabling wireless identification without line-of-sight requirements. Tags broadcast IDs when near readers, allowing dozens of tools to be scanned simultaneously. Systems can monitor movements through doorways or trucks, instantly flagging missing items. With both passive and active tag options, RFID offers flexibility and real-time visibility.

- Use cases:

RFID is widely adopted in construction tool tracking systems, manufacturing plants, utilities, and warehouses where high-volume tools and equipment must be tracked quickly without manual scanning. Fixed readers at gates can automatically log tools and link them to employees. A smart tool crib eliminates paperwork by tracking checkouts seamlessly and accurately. Handheld scanners also help locate lost items quickly using signal strength detection. - Pros & Cons:

The key benefit of RFID tool tracking is efficiency through automated data capture. Companies report major productivity gains and fewer missing tools after implementation. Although historically pricier than barcodes, falling costs make ROI highly attractive. In fact, recovered tools and efficiency improvements can unlock millions in added revenue.

GPS and Bluetooth (BLE) Tags – Tracking Beyond the Four Walls

For mobile or remote assets like generators, vehicles, or machinery, GPS tags are ideal. They provide real-time satellite positioning, perfect for tracking assets across job sites. Many solutions now use hybrid devices combining GPS, BLE, cellular, and Wi-Fi seamlessly. Indoors, GPS switches to BLE receivers, maintaining accurate tracking until signals return outdoors a core benefit of asset geo tagging in complex environments.

BLE tags function like rugged versions of consumer trackers, broadcasting signals to nearby devices. Unlike AirTags, enterprise-grade BLE tags are durable, weather-proof, and long-lasting. They enable geofencing, sending alerts when items cross unauthorized boundaries. This feature helps prevent theft by triggering alarms during unauthorized tool movements.

Choosing the right system:

Often, combining tagging technologies delivers the most effective and balanced results. Barcodes handle general inventory, RFID manages high-value items, and GPS secures mobile assets. Harsh environments may require specialty tags like anodized aluminum for durability. Similarly, metal tools need RFID-on-metal tags to avoid signal disruption and ensure accuracy.

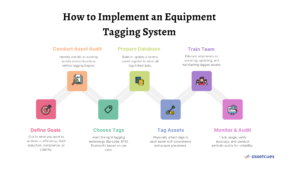

How to Implement an Equipment Tagging System (Step-by-Step)

Setting up a tagging system might sound daunting, but it can be broken down into manageable steps. Below is a proven approach to get your equipment tagging system up and running.

From defining goals and auditing assets to choosing tags, setting up software, and training teams, it outlines a practical path to accurate tracking. Moreover, regular monitoring and audits ensure the system stays reliable, scalable, and effective over time.

-

Define Your Goals and Scope:

Start with strategy by identifying which assets to tag and the purpose. Define whether goals include theft prevention, maintenance tracking, or multi-location visibility. Clear objectives and asset lists will guide every subsequent tagging decision. Additionally, involve stakeholders early to ensure organizational buy-in and address all concerns.

-

Conduct an Asset Audit:

Before tagging, conduct a thorough inventory audit of all tools and equipment. Record details like name, category, location, condition, and asset value accurately. This baseline ensures visibility and eliminates outdated or incomplete records company-wide. It also helps prioritize high-value or frequently moved items for tagging first.

-

Choose the Right Tags & Technology:

With goals and inventory set, choose tagging methods aligned with your needs. Factor in environment, scanning range, durability, and per-tag budget carefully. Indoor setups may prefer QR labels, while rugged RFID suits outdoor or high-value tools. Also, plan secure attachment—labels for basics, plates or epoxy for heavy-use assets.

-

Prepare Your Asset Database (Software):

Tags only work effectively when paired with a strong management system. Set up asset tracking software or a database to link tag data. A cloud-based platform like AssetCues enables real-time tracking, automation, and detailed reporting. Ensure fields include asset name, ID, location, user, and maintenance, creating a single reliable asset register.

-

Tag Your Assets Systematically:

Now comes the hands-on step—affix tags consistently and register each asset immediately. Place tags in standardized, scannable spots like handles or flat surfaces. Work in organized batches by location or category to ensure efficiency and accuracy. Finally, secure critical tags with tamper-evident or permanent methods, maintaining strict 1:1 correspondence with digital records.

-

Train Your Team and Establish Processes:

A tagging system succeeds only when employees use it consistently every day. Train staff on checking tools in and out, scanning, and reporting issues. Make tagging part of SOPs—maintenance, warehouse, and transfers must always include scans. Building accountability ensures tagging becomes routine, unlocking the system’s full benefits.

-

Monitor, Audit, and Optimize:

After implementation, schedule regular audits to reconcile physical assets with database records. Periodic checks reveal missing tags or assets, enabling quick corrective action. Monitoring usage data highlights idle tools or recurring losses requiring process improvements. Ongoing review and optimisation of asset tagging and tracking systems strengthen asset control, improve accountability, and ensure long-term effectiveness of the overall equipment management strategy.

Key Takeaways

- Overall, tool and equipment tagging transforms loose tools into traceable assets, reducing loss, theft, and downtime across construction, manufacturing, and field operations.

- Moreover, combining the right tagging technology (barcodes, RFID, GPS/BLE) with asset tracking software improves visibility, accountability, and audit readiness, even across multiple job sites.

- Finally, a well-implemented tagging process delivers fast ROI through fewer replacements, better utilization, and stronger operational control, making loss prevention a measurable business outcome.

Conclusion and Next Steps

Tool and equipment tagging goes beyond barcodes, creating workflows where assets are always accounted for. The right mix of tagging technologies and processes ensures peace of mind for managers. Maintenance teams gain reliable data, while Finance benefits from accurate, compliant records. Ultimately, tagging builds efficient, data-driven operations that save time, reduce risk, and cut costs.

Looking ahead, emerging technologies like BLE and IoT sensors enhance tagging capabilities significantly. Smart tags now track location while monitoring usage and conditions in real time. Adopting these innovations reduces losses further and improves workplace safety effectively. Still, success begins with mastering the basics—always knowing what you own and where.

Ready to begin? Start with a small pilot program by tagging selected tools. Trial an asset tracking app to immediately test visibility and efficiency improvements. As highlighted, tagging investments usually pay for themselves very quickly. Acting now safeguards assets, streamlines operations, and prevents costly project disruptions or tool losses.

Take the Next Step: Learn more about how AssetCues can help you implement a robust tool tracking solution. Visit our website to explore our asset tracking software and equipment checkout system features, or request a demo to see how our equipment tagging system can save you time and money. Let’s ensure that not a single tool goes missing on your watch – and that your team has exactly what they need, when and where they need it.

FAQ: Tool and Equipment Tagging Best Practices

Q1: What’s the best way to tag tools and equipment so they don’t get lost?

Ans: The best way to prevent tool loss is to combine durable asset tagging, asset tracking software, and consistent processes. First, assign every tool a unique, tamper-resistant barcode, QR code, or RFID tag. Next, track assets in centralized software to log locations, check-ins, and usage in real time. Additionally, enforce check-in/check-out procedures to create clear accountability. Finally, train teams and perform regular audits to maintain accurate records and quickly recover missing equipment.

Q2: How do equipment tagging systems help prevent theft?

Ans: Tagging systems deter theft by making assets visibly trackable and discouraging misuse. Real-time alerts, like geofence triggers, notify management of unauthorized removals instantly. Linking tools to employees through scans or badges builds clear accountability. Even if theft occurs, data on location, time, and custodian supports swift recovery.

Q3: What tags work best for heavy machinery in harsh environments?

Ans: In harsh environments, durable tags such as metal asset plates, on-metal RFID tags, and weather-resistant engraved labels work best. These tags withstand heat, moisture, abrasion, and outdoor conditions, thereby ensuring long-term readability and secure asset identification.

Q4: How much does an equipment tagging system cost?

Ans: The cost of an equipment tagging system varies by technology and scale. Basic barcode tagging is typically low-cost, while RFID-based systems require higher upfront investment but offer faster tracking and better automation for large or complex asset environments.